Ever had a consignment of finished rubber goods, pristine looking while packing and loading, only to be opened in the destination country, 20 days later, COVERED WITH BLOOM? These are not isolated incidents and bloom mostly does not really affect the product.

Rubber materials undergo a process called “blooming” when they are stored. “Bloom” is a milky dusting of dry powder on the surface of the rubber. Typically, this is caused by unused vulcanizing agent(s) migrating to the surface of the rubber part.

However, many companies have very strict standards and blooming in rubber products is not acceptable. These blooms are usually low molecular weight compounding ingredients such as curing agents, accelerators, processing aids and activators that migrate to the surface.

A word of caution though – excessive blooming can degrade the vulcanized rubber and reduce its quality. In production of multi-ply products such as tires, hoses, belts and other products; blooming reduces the tackiness of the rubber compound. Blooming of sulphur materials on uncured rubber compounds can give rise to poor rubber-to-rubber or rubber-to-metal bonding. Also, blooming of the accelerator component to the rubber surface often extensively damages the internal structure of the rubber matrices; creating cracks and voids which weaken the rubber mechanically

How does Blooming happen?

Rubber compounds are complex mixtures, consisting of different compounding ingredients such as curing agents, accelerator, processing aids, and activators; which may be in solid and/or liquid forms. Many of these compounding ingredients often blooms and diffuses to the surface during storage and service life.

Check out more information, in one of our earlier articles on blooming here

EPDM is more widely used as its standout feature is that it is highly resistant to UV, ozone, weathering and so are being used for sealing. This superior product has become standard in many industries, from construction to automotive. It has an outstanding ability to withstand ozone and UV, in addition to other environmental factors.

EPDM is widely used as follows in various industries

- Construction: weatherproofing and waterproofing, especially on roofs. It is also used as a sealant for garage doors, expansion joints, and as a liner for pools or tanks.

- HVAC: EPDM is useful with heating/cooling systems and can be used for tubes, seals, gaskets, and insulation.

- Automotive: EPDM is known to be flexible and resilient. This makes it very useful in cable harnesses, weather stripping, wire harnesses, sealant, brake systems, and more. It can also be used for car bumpers and fender extensions.

- Industrial: electrical insulation and waterproofing are key uses for EPDM. It can be implemented in water systems with gaskets, hoses, and O-rings and also insulate and connect cables and wires.

EPDM

Ethylene propylene diene rubber (EPDM) is a terpolymer with side-chain double bonds. The main chain thus remains saturated. The advantages of the EPDM’s largely saturated molecular structure, e.g., high resistance to weathering and ageing, are accompanied by a relatively stable vulcanization characteristic. An economically viable cross-linking of EPDM with sulphur often can only be practically achieved through complex systems with numerous individual components consisting a combination of vulcanization accelerators and sulphur donors.

In this case, when selecting and balancing the accelerator chemicals, one must take into account the limited solubility of each of the individual components in the EPDM polymer. If the components are not optimally balanced, along with other ingredients, fogging or blooming effects can appear on the surface of the vulcanized material.

Handling Blooming the Smart & Easy Way

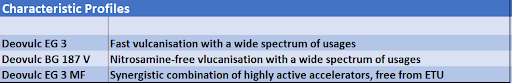

The table with the characteristic profiles should initially give you a brief overview of the individual features of the three Deovulc accelerator blends

Deovulc EG 3

For over four decades, DOG Deutsche Oelfabrik has been producing accelerator blends that enable balanced, safe, and blooming-free EPDM cross-linking in industrial usage, and has reached worldwide distribution. In place of conventional accelerator blends, DOG offers a reliable universal solution for EPDM cross-linking: Deovulc EG 3.

Deovulc BG 187 V

For vulcanization processes in which no nitrosatable secondary amines, and thus also no nitrosamines, can occur, DOG has developed a product line called the Deovulc BG-Accelerator Blends. Deovulc BG 187 V has proven itself, over the course of more than 20 years, to be a non-staining, non-blooming, highly-active accelerator blend based on zinc dithiophosphates and synergistic secondary accelerator combinations.

Deovulc EG 3 MF

It is a synergistic combination of highly active accelerators, free from ETU. It is a fast-curing primary accelerator blend for EPDM with freedom from blooming* and staining. Deovulc EG 3 MF replaces complex accelerator combinations in EPDM and enables good heat resistance and low compression set. Deovulc EG 3 MF is suitable for all common processing techniques such as extrusion or injection moulding. Deovulc EG 3 MF does not contain any SVHC or CMR substances according to REACH but offers a similar vulcanization characteristic to our well-established accelerator blend Deovulc EG 3.

*Due to the large number of ingredients in rubber-compositions we cannot guarantee non-blooming for all applications

Advantages of Using Deovulc Accelerator Blends

All Deovulc accelerator blends offer significant advantages with simple and reliable weighing and dosage. There is no need for the costly mixing of individual components. The Deovulc accelerator blends, in either powder or granulate form, allow for easy integration and demonstrate a high level of process-reliability.

With the Deovulc range of accelerator blends, DOG offers products which meet the demands of efficient and economical vulcanization of continually manufactured EPDM compounds. In additional to the advantage of faster and more accurate weighing, the Deovulc accelerator blends offer a high level of regularity in the crosslinking, and normally show no blooming effects. In addition to extrusion, these products generally are also suitable for usage in the standard production process of moulded articles.

** Technical details have been reproduced with appropriate permissions

I R Tubes Private Ltd., Pune are distributors for quality chemicals of Deutsche Oelfabrik of Germany, Omya UK Ltd., Robinson Brothers, UK, Emery Oleochemicals Ltd and Aquaspersions. Our chemicals are used in the manufacture of Rubber, Plastics, Latex, Adhesives and Sealants.

Raju Jethmalani

IRTubes Pvt. Ltd., Pune

Share on: