The permissible standard for Calcium Oxide is 5 milligrams of CaO per cubic meter of air averaged over an eight-hour work shift. Some countries have recommended 2 milligrams per cubic meter. CaO has been linked to many health hazards like irritation of the eyes, nose, throat and skin. Severe burns may result from contact with this chemical. It may also cause bronchitis and pneumonia. Long term exposure is said to cause skin ulceration and perforation of the nasal septum.

Factories and manufacturing units that use CaO in their processes mostly have very detailed safety guidelines. It is, therefore, obvious that although there is a need to use CaO, one must be aware of the downside of the chemical.

Use of a desiccant like calcium oxide can have important cost-effective benefits in processing rubber, eliminates the need for pre-drying and avoids porosity and metal corrosion problems.

However, given the downside of use of CaO the rubber industry needs to look at ways to mitigate this issue.

In the manufacture of profiles for the rubber industry, whilst compression set must be maintained, one has to use a desiccant like CaO to reduce moisture, which can be harmful. Our purpose here is to show you ways to ensure safe use of desiccants

Microwave Vulcanization Ovens

Microwave as a heating technology is a faster, more efficient heating method for non-conducting materials. Its adaptability to increased automation and electronic control helps it to easily integrate into high-speed operations.

Microwave radiation penetrates the rubber and heats the material from core to surface simultaneously and hence microwave curing is very fast. Microwave heating has proved suitable equally for sponge, solid and co-extruded profiles. Despite, this technology, a fair amount of moisture still exists.

What is Compression Set and why is it important?

Compression set is the measure of how much a rubber material will permanently deform under a constant load. It is important to stabilize compression set in rubber because it can affect the performance and durability of the rubber. If it is too high, it can cause the rubber to lose its shape and become less effective at sealing, cushioning or transmitting force. This can lead to failure of the rubber component and the overall system it is a part of. Stabilizing compression set can help ensure that the rubber retains its shape and performance over time, making it more reliable and longer-lasting. For e.g., if a material is deformed (compressed) for a given period. Then after a 30-min recovery time, the sample is measured. The value derived is the percentage a material sample that fails to recover its original height. For example, a compression set of 40% states that the material regained only 60% of its uncompressed thickness.

As a rubber material is compressed over time, it loses its ability to return to its original thickness. This loss of resilience may reduce the capability of an elastomeric gasket, seal or cushioning pad to perform over a long period of time. The resulting permanent set that a gasket may take over time may cause a leak.

There are several ways to stabilize compression set in rubber

- Using high quality rubber material to minimize deformation under load

- Adding fillers to the rubber to increase its stiffness and reduce deformation

- Cross-linking increases its molecular weight and makes it more resistant

- Using a rubber compound with a higher durometer (hardness)

EPDM (ethylene proplylene diene monomer) is used to produce profiles, as this synthetic rubber is known for its excellent properties There are various new technologies that can be used to improve the moisture resistance of CaO containing EPDM profiles.

The Use of Desiccants in Rubber to absorb moisture

Dessicants such as CaO are often used in rubber to help prevent the rubber from deteriorating due to moisture. However, there are some drawbacks to some dessicants:

- They can be abrasive and cause wear on the rubber over time. This can reduce the lifespan of the rubber and lead to premature failure.

- Another issue is that they can be toxic or harmful to humans or to the environment. Some dessicants such as silica gel, are not considered toxic, but others, such as calcium oxide can be dangerous if inhaled or ingested.

- They may be ineffective at removing all moisture from the rubber, especially in high humidity environments.

Overall, the effectiveness of these new technologies in improving the moisture resistance of EPDM profiles will depend on the specific technology being used and the application it is being used in.

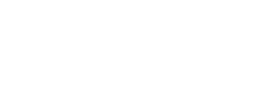

Use of Deostab Negates the Drawbacks of Using CaO as a desiccant whilst obtaining good Compression set

Deostab is a vulcanization stabilizer that improves the state of cure and the compression set by reducing the negative influence of CaO in the vulcanisation characteristic without affecting the desiccant action of calcium oxide.

The following shows formulating CaO containing EPDM compounds with excellent performance properties

Deostab, a chlorine containing factice which improves state of cure and compression set without affecting the desiccant action of CaO

Basic compound: EPDM 4% EN 100, N 774 carbon black 120, Paraff oil 50, stearic acid 1, ZnO 5, Sulphur 1, N-nitrosamine forming acceleration: 4 Deovulc EG 3, N-nitrosamine free acceleration, 5 Deovulc BG187, Cure 15/165 degrees Centigrade, compression set 22h/100 degrees Centigrade

The benefits of using Deostab that it is primarily used for EPDM profile compounds, BfR (German Federal Institute for Risk Assessment) suitable, does not contribute to blooming and is particularly suitable for nitrosamine-free systems.

I R Tubes Pvt. Ltd. is a leading specialty chemical suppliers for the chemical industry. Contact I. R. Tubes on info@irtubes.com or Call: 9689927193 for more information