There seems to be no end in sight, at least in the immediate future for an end of the Russia-Ukraine conflict. Reports on the conflict that once dominated headlines, now finds a small mention on page six or seven of newspaper. What does remain is the economic turmoil that the conflict has caused across the globe. Countries have been directly or indirectly impacted as Russia and Ukraine are the biggest exporters of raw materials around the world. Before the conflict, Ukraine had a thriving synthetic chemical sector where thousands of novel compounds were being produced. A fall out of this is that the booming chemical industry in Germany has been affected. The chemical industry depends on gas for 30% of its output and 44% for its energy consumption. 17% of the German chemical companies depend on Russian import of raw materials. Apart from shortage of raw materials and intermediate products, we can add logistical woes to the mix. In some instances, raw materials are completely unavailable and manufacturers have had to resort to alternate chemicals.

More specifically very specialized products like OTOS and cure packages containing OTOS have been taken off the market. N-oxydiethylenethiocarbamyl – N -Oxidiethylene-sulfenamide (OTOS) is a specialised product to produce rubber vulcanisates with a high content of mono and di-sulfidic crosslinks. The benefits of OTOS are that it has high reversion resistance, low heat build-up and low compression set can be achieved. It improves the reversion stability as well as the mechanical and dynamical properties of rubber articles. In engine mount applications a reduction of compression set and an improvement of oxidative stability has been noticed. It has been proven to be very effective for anti-vibration applications.

OTOS is such an important component in many fields and not having it is impacting many customers of D.O.G., a big player in the Speciality chemicals sector, with a view to serving their customers they have introduced a new product as substitute for OTOS.

In this month’s article we bring to you an alternative acceleration blend Deovulc BG 223 to substitute Deovulc EG 28 and OTOS 80 in natural rubber, through the following:

General Aspects

Following are the recipes of BG 223 in comparison to EG28 and OTOS 80:

| Recipes | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| NR | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Carbon Black | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 |

| Plasticizer | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Stearic Acid | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Zinc Oxide | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Dispergum E | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Deovulc BG 223 | 1.0 | 1.5 | 2.0 | 2.5 | ||||||||

| Deovulc EG 28 | 1.0 | 1.5 | 2.0 | 2.5 | ||||||||

| Deovulc OTOS 80 | 1.0 | 1.5 | 2.0 | 2.5 | ||||||||

| Deosulf L 95 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Total phr | 162.0 | 162.5 | 163.0 | 163.5 | 162.0 | 162.5 | 163.0 | 163.5 | 162.0 | 162.5 | 163.0 | 163.5 |

Table 1: Recipes of Deovulc BG 223

Rheology

| RPA flex 180°C/6 min | S’ min (Nm) | S’ max (Nm) | T10 (min) | T50 (min) | T90 (min) |

| BG 223 – 1.0 phr | 1.21 | 9.72 | 0.52 | 0.80 | 1.31 |

| BG 223 – 1.5 phr | 1.29 | 10.25 | 0.53 | 0.74 | 1.17 |

| BG 223 – 2.0 phr | 1.38 | 11.34 | 0.49 | 0.67 | 1.03 |

| BG 223 – 2,5 phr | 1.40 | 12.31 | 0.50 | 0.67 | 1.05 |

| EG 28 – 1.0 phr | 1.51 | 9.51 | 0.38 | 0.54 | 0.80 |

| EG 28 – 1.5 phr | 1.52 | 10.56 | 0.35 | 0.50 | 0.73 |

| EG 28 – 2.0 phr | 1.54 | 11.57 | 0.34 | 0.48 | 0.71 |

| EG 28 – 2.5 phr | 1.55 | 12.35 | 0.33 | 0.47 | 0.70 |

| OTOS 80 – 1.0 phr | 1.55 | 7.60 | 0.43 | 0.87 | 1.50 |

| OTOS 80 – 1.5 phr | 1.50 | 8.54 | 0.45 | 0.83 | 1.35 |

| OTOS 80 – 2.0 phr | 1.50 | 9.47 | 0.45 | 0.80 | 1.30 |

| OTOS 80 – 2.5 phr | 1.47 | 10.37 | 0.47 | 0.80 | 1.37 |

Table 2: Rheological measurements of the tested mixtures from Table 1

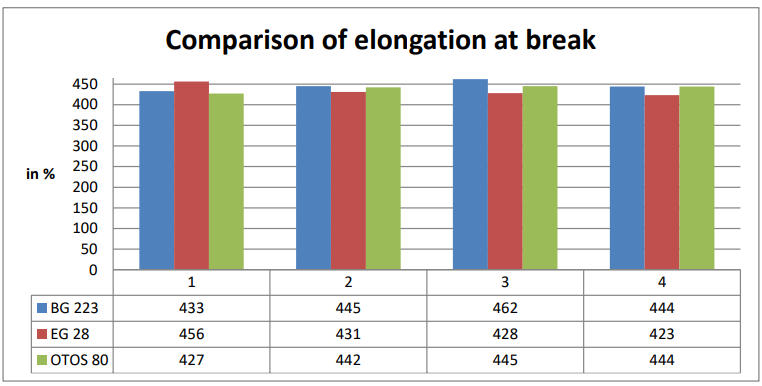

Physical Properties

| Vulcanization:

10 Min/170° C, S2- Specimen |

Modul 100% (MPa) | Modul 300% (MPa) | Tensile Strength (MPa) | Elongation at Break (5) | Hardness Shore A |

| BG 223 – 1.0 phr | 1.5 | 9.7 | 19.8 | 443 | 49 |

| BG 223 – 1.5 phr | 1.7 | 11.1 | 23.7 | 445 | 51 |

| BG 223 – 2.0 phr | 2.1 | 13.0 | 26.8 | 462 | 53 |

| BG 223 – 2,5 phr | 2.3 | 13.8 | 26.6 | 444 | 54 |

| EG 28 – 1.0 phr | 1.6 | 10.0 | 22.6 | 456 | 49 |

| EG 28 – 1.5 phr | 2.0 | 12.9 | 23.9 | 431 | 51 |

| EG 28 – 2.0 phr | 2.4 | 14.6 | 26.0 | 428 | 54 |

| EG 28 – 2.5 phr | 2.6 | 15.5 | 26.6 | 423 | 55 |

| OTOS 80 – 1.0 phr | 1.3 | 8.0 | 16.2 | 427 | 46 |

| OTOS 80 – 1.5 phr | 1.6 | 10.1 | 20.1 | 442 | 49 |

| OTOS 80 – 2.0 phr | 2.0 | 12.1 | 24.8 | 445 | 52 |

| OTOS 80 – 2.5 phr | 2.1 | 12.9 | 25.1 | 444 | 53 |

Table 3: Physical measurement of the tested mixtures from Table 1

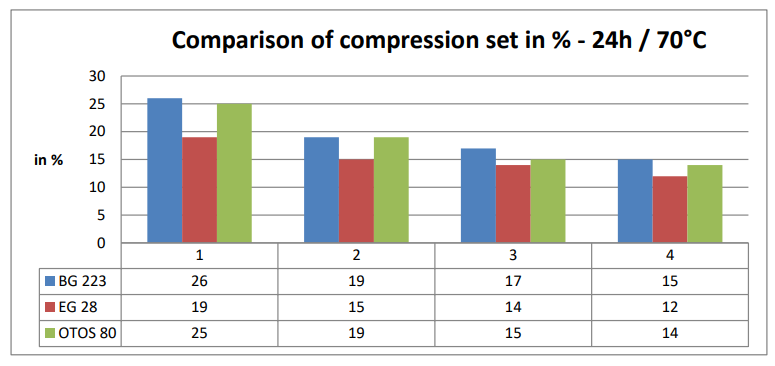

Compression Set

| Vulcanization: 10 Min/170° C | 24h/70° C | 24h/100° C |

| BG 223 – 1.0 phr | 26 | 52 |

| BG 223 – 1.5 phr | 19 | 45 |

| BG 223 – 2.0 phr | 17 | 40 |

| BG 223 – 2,5 phr | 15 | 36 |

| EG 28 – 1.0 phr | 19 | 32 |

| EG 28 – 1.5 phr | 15 | 27 |

| EG 28 – 2.0 phr | 14 | 24 |

| EG 28 – 2.5 phr | 12 | 22 |

| OTOS 80 – 1.0 phr | 25 | 42 |

| OTOS 80 – 1.5 phr | 19 | 31 |

| OTOS 80 – 2.0 phr | 15 | 27 |

| OTOS 80 – 2.5 phr | 14 | 24 |

Table 4: Compression set of the tested mixtures from Table 1

Summary and conclusion

Different experiments have been conducted to compare Deovulc BG 223 with Deovulc EG 28 and Deovulc OTOS 80 in NR mixtures. After evaluation of the results, it has been demonstrated that Deovulc BG 228 represents a good substitute for Deovulc EG 28 and Deovulc OTOS 80.

Regarding the rheology, the crosslinking density and the vulcanization speed are comparable, the mechanical value area almost identical to those of EG 28 and OTOS 80. Hardness is comparable to each other. Regarding the compression set, the results are almost identical compared to each other.

As the chemical industry that fulfils the requirements of almost every industry such as raw material sourcing, processing, refinery, desalination, etc. is being severely impacted with the supply chain crunches caused by the Russia-Ukraine war. However, industry players are looking for alternative sources and strengthening domestic supply chain to pace their production and fulfil the evolving demands of consumers.

I R Tubes Pvt. Ltd. is a leading specialty chemical suppliers for the chemical industry. Contact I. R. Tubes on info@irtubes.com or Call: 9689927193 for more information